If you operate a delivery fleet, you could be sitting on a goldmine of incremental profit and customer goodwill – and not even know it.

Whether you’re a distributor, manufacturer or retailer, your trucks and drivers suck up a huge percentage of operating expenses. Efficiency gains in fleet performance can deliver six- or seven-figure savings straight to your bottom line, while improving delivery service in the process.

The key to unlocking these benefits: route optimization. Basically, making sure your fleet operates at maximum efficiency, every day.

It’s a term used mainly by fleet managers, but one whose impact resonates powerfully throughout a distribution business – from the dispatch room to the board room.

In this guide, we’ll explore all aspects of route optimization – from the nuts and bolts of how it’s done to advanced optimization strategies for larger fleets.

Route optimization is the process of determining the most efficient route for a vehicle to take based on a set number of stops and all the outside variables that can impact the journey.

It’s a software-aided process that can realistically cut fleet operating costs 10–30 percent and significantly increase customer satisfaction by reliably meeting ETA objectives.

Fleet operators that have prioritized route optimization enjoy the following competitive advantages:

By reducing the amount of time and miles it takes for trucks to complete routes, over time you reduce the cost for trucks, drivers and all other vehicle operating costs. Below is a breakdown of truck operating costs, by percentage of total costs, based on data from the American Transportation Research Institute (ATRI). Route optimization reduces every one of these cost buckets.

| TRUCK OPERATING COSTS | % of Total |

| VEHICLE-BASED | |

| Fuel costs | 23% |

| Truck/Trailer lease or purchase payments | 14% |

| Repair & maintenance | 12% |

| Truck insurance | 4% |

| Permits/Licenses | 1% |

| Tires | 2% |

| Tolls | |

| DRIVER-BASED | |

| Wages | 35% |

| Benefits | 7% |

| TOTAL | 100% |

A Walker study found that customer experience has overtaken product and price as the key brand differentiator. The final mile presents an ideal opportunity for distributors to enhance this customer experience. By creating more accurate routes, your customers develop greater confidence in your ability to meet delivery promises. Reliably satisfying customer expectations makes them more likely to stay and, according to Bain and Company (the inventors of Net Promoter Score), a 5 percent increase in customer retention produces more than a 25 percent increase in profit.

Manually organizing multi-stop routes for an entire fleet is painfully time consuming. Specialized route optimization software has built-in algorithms that help you to quickly adapt delivery operations to meet changing customer requirements or company strategies. Here are just a few examples where automation allows you to plan changes in literally minutes versus hours:

It’s a mistake to view route optimization as purely the concern of the transportation team. Better fleet performance leads to improvements across the business. As your delivery service becomes more reliable and efficient, you create an organization that, overall, is more agile and customer-centric. That’s a pretty good formula for competitive advantage.

Efficient management of delivery fleets has become more complex, and more critical than ever before as customer expectations rise and industry trends put further pressure on fleet operators. Here are just some of the factors impacting today’s fleets:

Customers increasingly want more precisely timed deliveries. In general, there’s an “Amazonization” of freight, with both B2C and B2B customers expecting fast, accurate deliveries at the same or lower cost.

As supply chains get leaner, that means less inventory on the shelf, in the warehouse and on the production line. It also means smaller, more frequent shipments delivered just in time – and that translates into more complex delivery requirements.

Customers want visibility to exactly when products will arrive, whether it’s delivery of fresh grocery products to a convenience store or animal feed to a farm. Businesses that know this information can schedule people to receive the products, ready the receiving area and, in general, gain the efficiencies that come from good advanced planning.

Fuel accounts for about 25 percent of the cost of a truck-mile. The heat is on to make the most of every single mile driven in order to mitigate the financial impact of diesel fuel cost hikes.

To address congestion and environmental concerns, municipalities are increasingly restricting commercial deliveries during certain hours, adding to the complexity of route planning.

According to the American Trucking Association (ATA), the industry is short at least 50,000 drivers. The average age of a US truck driver is 55 (Bureau of Labor Statistics), so the shortage will worsen as these drivers retire. Attracting new drivers is expensive and difficult, so it’s more critical than ever that route plans get the most out of the existing driver force.

These complexity-driving trends all lead to one conclusion: without the aid of transportation route optimization software to address routing challenges, fleet managers simply can’t generate an optimized plan in the allotted time. As customers change and new stops are added, profit-draining inefficiencies creep in without anyone noticing.

So how does route optimization help?

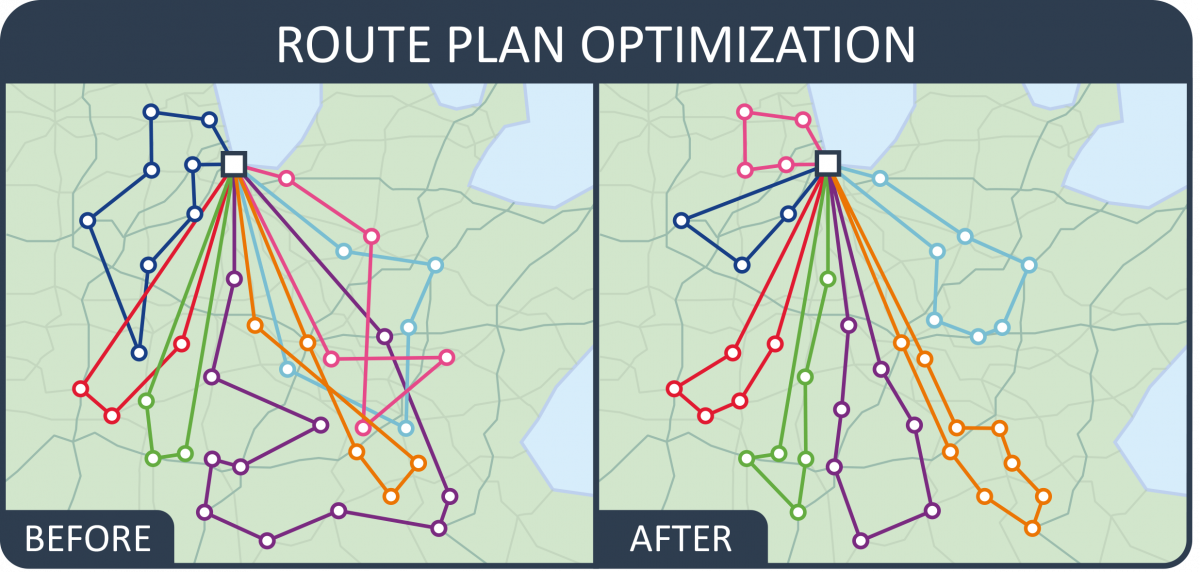

Here’s a picture of the daily delivery path of just seven vehicles before and after route optimization.

On the “before” image, routes clearly overlapped, which added more than 10 percent more cumulative miles than needed. Using the pre-optimized route plan, the company would:

Bottom line: delivery fleets that are inefficient can suck your profits dry. Delivery schedules that are unreliable erode customer confidence.

What if someone asked you how they could quickly compute a difficult math equation?

You could explain the process, but for most the simple answer would be “use your smart phone app.”

It’s much the same for the question of how to optimize truck routes. Manual methods are cumbersome, time-consuming, less accurate and, most importantly, not necessary. Routing software is purpose-built to quickly arrive at the best route combinations from millions of possible options. It’s a case where the human brain is no match for smart algorithms and a powerful computer.

For a simple routing problem involving 10 vehicles and 10 calls per vehicle, the number of route permutations is approximately 125,631,301,911,058,944,000.

Even if we could evaluate 1,000 options per second, the exercise would take almost 4 billion years. Specialized route optimization software can handle the same analysis in minutes.

Optimized routing solutions use complex algorithms to calculate the most efficient routes. But the underlying principle of smart routing is quite simple. It combines what you know (your customers, what products they want and within what delivery windows) with what is knowable (things like average road speeds at different times of the day, the location of low bridges or other barriers that require a different route, and dozens of other variables). It then calculates the most efficient way to deliver, while still meeting customer expectations.

There are many benefits to delivery route optimization. Among them are reduced costs, improved customer service and lower carbon emissions. Let’s look at each of these benefits.

In our 30 years of routing experience, we’ve found that, on average, businesses that optimize delivery performance with routing software can reduce fleet operating costs 10–30 percent, with the least automated operations being at the high end of that savings range.

Say you’re a distributor with 20 trucks in your fleet, each logging an average of 50,000 miles per year. That amounts to total annual fleet miles of 1 million. By applying the National Private Truck Council’s average fleet mile cost of $2.72 (fully loaded), we can put the yearly operating cost of that fleet at about $2,720,000. When you cut fleet miles 15 percent, costs are reduced to $2,312,000 for a yearly savings of $408,000 – savings that you continue to enjoy in each successive year.

Let’s unpack these savings. Where do they come from?

Route optimization not only makes routes more efficient; it makes them accurate with highly reliable ETAs. This greatly enhances customer service. Happy customers stay, and some might even pay a little more for the benefit of reliable delivery.

Let’s look at just some of the ways route optimization software improves the customer experience.

The first principle of sustainability when it comes to hauling freight by truck is to burn less fuel. And the easiest way to do that is to reduce fleet miles. One of our foodservice customers cut more than 1 million miles from their operation a year. That’s a lot less carbon being released into the atmosphere.

But green freight practices encompass more than simply finding the shortest way of going from A to B to C to D on a multi-stop delivery trip. It enables other fleet optimization practices that save fuel and emissions. Here are a few:

When it comes to freight, fuel consumption is the element that really matters. A fully optimized delivery fleet burns less fuel and emits less CO2. It really is that simple.

Advanced route optimization software has capabilities that can go far beyond “plan today for tomorrow’s deliveries” functionality. Let’s look at just a few strategies that can pave the way for dramatic cost savings and customer service improvements.

Integrating these two systems allows you to automatically identify discrepancies between planned and actual performance and adjust accordingly. Benefits include:

Powerful modeling tools let you explore any number of changes using your actual data to assess the precise implications of the change on cost and service. Examples of questions that such tools can answer include:

UK Blakemore Logistics distributes to 1,100 SPAR stores located across England and Wales. The company is targeting continuous improvement by using Paragon’s software to model different aspects of its distribution operation to understand the benefits of any proposed changes. The company can create multiple scenarios using its own transport data to gain better operational insight and make informed business decisions regarding its network and fleet profile.

Often fleet operators fail to explore strategic questions because they lack the time and resources required to do the analysis manually. A modest investment in route optimization software lets you run “what if” modeling exercises to explore strategies that can deliver dramatic cost savings.

Sometimes, in an effort to close a deal, over-zealous salespeople can make expensive promises to new customers before understanding the true cost to serve that customer. It’s a difficult analysis to do without sophisticated software designed for the purpose. That’s because no Excel spreadsheet can cope with the complexity involved. Exactly where are the new delivery points? When are they open to receive delivery? What is the normal order size and how will it vary? How will these deliveries fit in with other existing deliveries?

Route optimization software models these and other factors to develop the best routing plan for the new locations and the impact of the changes on margin. Not all new business is good business. Sometimes it takes careful analysis to make that determination.

Beyond these efficiency-driving optimization strategies, the data you gather from your delivery operation can provide a constant flow of intelligence that makes the business smarter. The data answers questions that aid decision-making at just about every level in just about every department – from customer service to the corner office.

The most efficient delivery route plan is still only that – a plan. Unless that plan is executed by your drivers, none of the benefits accrue. That’s why it’s so critical to make an effective driver debrief part of your overall route optimization program.

The driver debrief is a quick, post-route discussion to determine if routes went as planned and, if not, why not.

Avoiding the driver debrief is like a business spending $50,000 on advertising to grow sales and not asking how the ads performed. If you’re not regularly assessing routes with drivers, your routes are likely performing about as well as that poorly monitored advertising program.

Questions asked during a debrief will depend what the available data suggests about the route and how it deviated from plan. Some examples:

The answers may suggest a need for the driver to better follow the plan or a need to change the plan to align with the reality of driving conditions and time required at drop points.

The nature of the driver debrief will be very, very different depending on whether or not live data from your in-cab telematics is integrated with your route optimization software.

Without telematics data, you are relying on the driver to record events manually, like when the route started and ended, the length of time for each drop, and any difficulties encountered along the way. Depending on a driver’s memory is just not reliable.

With telematics data integrated with your routing software, discussions with drivers will be based on actual performance. There’s no hiding the fact that the driver went 20 miles off the planned route. The only question is why.

Truck drivers enter the profession, in part, because there is an element of freedom and independence. When businesses view post-route debriefs solely as a means to monitor drivers and hold them accountable, they strike a dissonant chord.

The best driver debriefs are not “us vs. them” discussions. They are about manager and driver teaming up to create a win-win outcome for better truck route planning.

Interactions with drivers should underscore the value of their input and the collaborative nature of the debrief process. Drivers hold the key to continually fine-tuning routes to both improve company performance and drivers’ quality of life.

How fast will you see a return on a route optimization system?

In our experience, ROI is realized within a year and can be as fast as three months.

The actual cost of route optimization software can vary from $25,000 for simple installations to hundreds of thousands for very large fleets with sophisticated routing requirements. The ROI calculation will differ depending on whether it is installed software with an up-front cost or a SaaS solution with an ongoing monthly payment.

A simple way to put a cost savings number against this investment is to multiply your total annual fleet miles by NPTC’s $2.72 cost-per-mile estimate, then multiply this sum first by 10 percent to identify the lower end of the savings range and then by 30 percent to identify the higher end of the range.

Some savings are clear and measurable for an ROI calculation. Others, not so much.

We’ve already reviewed the main sources of the hard dollar savings. If you complete your routes in less time and fewer miles, you can, over time, reduce the size of your fleet and driver force, while you also cut fuel and fleet maintenance costs.

In addition, there are other softer benefits that pack quite a punch, but may not be factored into an ROI calculation:

It’s important to remember that all savings from route optimization software continue year on year, so the lifetime boost to the bottom line could be enormous.

There is no set formula for measuring the success of your route optimization program. Obviously, there is a cost component and a customer service/satisfaction component. But the benefits of efficient fleet operations can reach far beyond truck miles and costs. For a distribution business, your entire value proposition is built on the foundation of reliable delivery.

Your first step should be to select the metrics that are most important to your business and establish an accurate baseline. The below list details just some of the key performance indicators fleet operators look at to assess program effectiveness. Focus on the metrics that mean the most to your business and measure them religiously and accurately.

Sample route optimization success metrics include:

Beyond some of these more obvious fleet efficiency metrics, route optimization software can drive value well beyond the transport department. Some examples:

Clearly, your trucks can provide a goldmine of actionable intelligence – if you’ve got the tools to monitor and report on fleet performance.

In today’s economy, route optimization is a vastly under-rated strategy for business success.

From a customer service perspective, expectations for more frequent, precisely timed deliveries have never been greater. And the bar is rising every day. It’s become very difficult for companies to differentiate on product and price, but excellence in delivery is a highly valued and achievable competitive lever.

From a cost perspective, private fleets represent a huge percent of total operating expenses – and a huge drain on profits if they are not managed well.

For businesses that continue to rely on manual methods to plan delivery routes, there’s never been a more opportune time to make a case for automating the process.

But the effort needs a champion. Maybe you?

Hopefully, this comprehensive look at route optimization can help make the business case.

Thank you for subscribing to updates from Paragon.